Competitive Price for Reach Compliant Bisphenol a 80-05-7 Technical Grade Polymers ISO Tanks

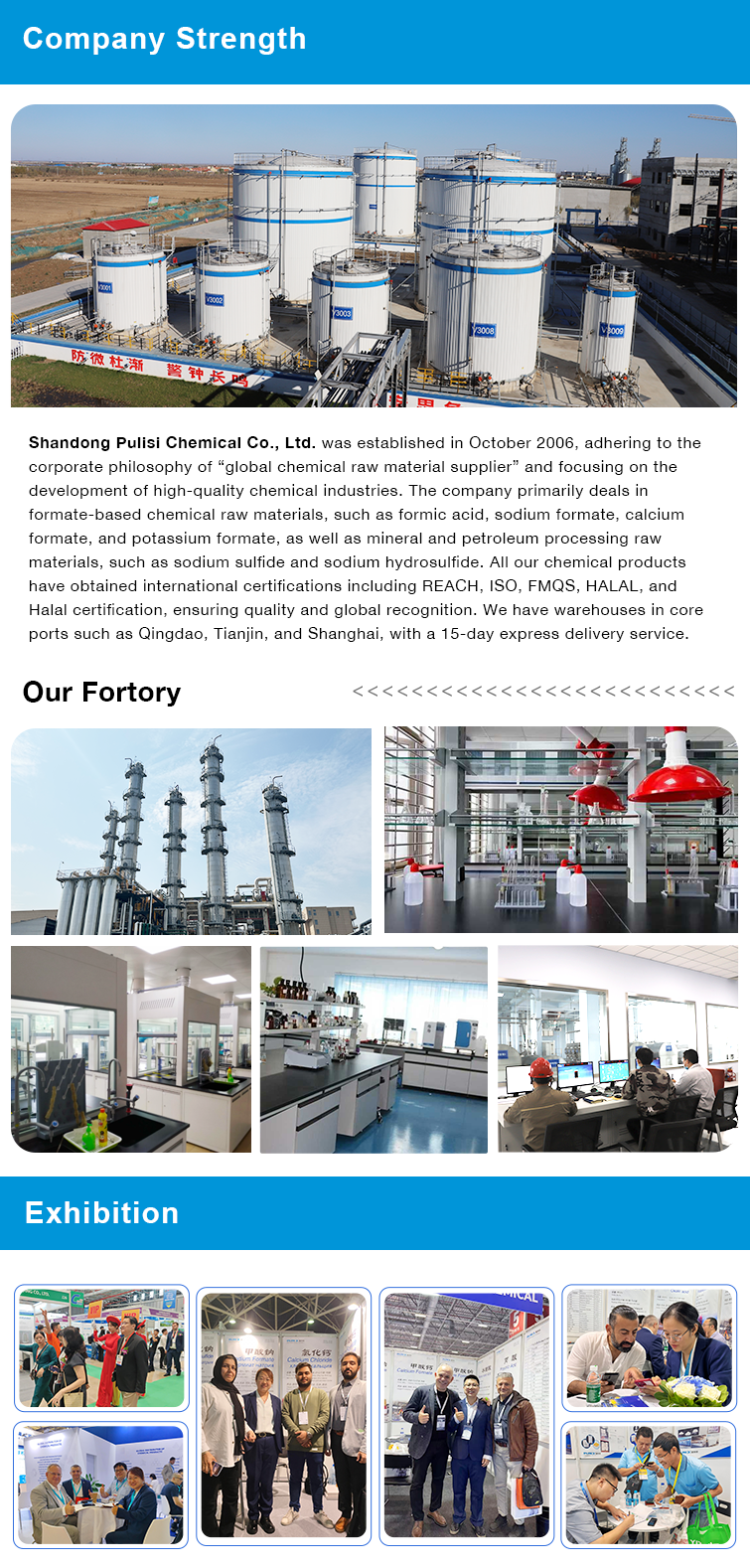

We pursue the management tenet of “Quality is remarkable, Company is supreme, Name is first”, and will sincerely create and share success with all clientele for Competitive Price for Reach Compliant Bisphenol a 80-05-7 Technical Grade Polymers ISO Tanks, Our aim is to help customers realize their goals. We are making great efforts to achieve this win-win situation and sincerely welcome you to join us.

We pursue the management tenet of “Quality is remarkable, Company is supreme, Name is first”, and will sincerely create and share success with all clientele for , On today, we’ve got customers from all over the world, including USA, Russia, Spain, Italy, Singapore, Malaysia, Thailand, Poland, Iran and Iraq. The mission of our company is to deliver the highest quality products with best price. We’ve been looking forward to doing business with you!

The storage conditions for bisphenol A should revolve around the core objectives of “preventing deterioration, ensuring safety, and avoiding environmental impact”.

Uses of Bisphenol A (BPA)

Bisphenol A (BPA) is an essential raw material for the synthesis of polycarbonates, epoxy resins, and high-temperature resistant polyesters. It is also used as a PVC stabilizer, plastic antioxidant, UV absorber, fungicide, etc.

As a versatile compound, BPA is extensively employed in the production of epoxy resins, polycarbonates, polyester resins, polyphenylene ether resins, and polysulfone resins. Additionally, it serves as a stabilizer for polyvinyl chloride (PVC), an antioxidant in plastics, a UV absorber, an agricultural fungicide, and an anti-aging agent in rubber.

It is also utilized as an antioxidant and plasticizer in paints and inks. In organic synthesis, BPA acts as a key ingredient for manufacturing epoxy and polycarbonate resins, and it is widely applied as an important raw material for high-molecular synthetic compounds, as well as in anti-aging agents, plasticizers, and agricultural fungicides.

1. Delivery Reliability & Operational Excellence

Key Features:

Strategic inventory hubs at Qingdao, Tianjin, and Longkou port warehouses with 1,000+

metric tons of stock available

68% of orders delivered within 15 days; urgent orders prioritized via express logistics

channel (30% acceleration)

2. Quality & Regulatory Compliance

Certifications:

Triple-certified under REACH, ISO 9001, and FMQS standards

Compliant with global hygiene regulations; 100% customs clearance success rate for

Russian imports

3. Transactional Security Framework

Payment Solutions:

Flexible terms: LC (sight/term), TT (20% advance + 80% upon shipment)

Specialized schemes: 90-day LC for South American markets; Middle East: 30%

deposit + BL payment

Dispute resolution: 72-hour response protocol for order-related conflicts

4. Agile Supply Chain Infrastructure

Multimodal Logistics Network:

Air freight: 3-day delivery for propionic acid shipments to Thailand

Rail transport: Dedicated calcium formate route to Russia via Eurasian corridors

ISO TANK solutions: Direct liquid chemical shipments (e.g., propionic acid to

India)

Packaging Optimization:

Flexitank technology: 12% cost reduction for ethylene glycol (vs. traditional drum

packaging)

Construction-grade calcium formate/Sodium Hydrosulfide:Moisture-resistant 25kg woven PP bags

5. Risk Mitigation Protocols

End-to-End Visibility:

Real-time GPS tracking for container shipments

Third-party inspection services at destination ports (e.g., acetic acid shipments to South Africa)

After-Sales Assurance:

30-day quality guarantee with replacement/refund options

Complimentary temperature monitoring loggers for reefer container shipments

The material and tightness of the Bisphenol a equipment are crucial. Equipment such as reaction kettles need to be made of special corrosion-resistant materials, such as stainless steel, to ensure that they are not corroded in harsh reaction environments such as acidic conditions. At the same time, good tightness can prevent material leakage and the entry of external impurities.The impurity content during the production process should be strictly monitored. For example, impurities such as metal ions should be controlled below the ppm level. These impurities may poison the catalyst, reduce the reaction activity, and ultimately affect the quality of bisphenol A BPA products.